Our company is one of the few manufacturers of metal and plastic positions in Bosnia and Herzegovina that has an integrated system of development and production of tools, injection molding of plastic products and precision machining.We develop and produce high-quality plastic injection tools for almost any type of thermoplastic (PP, PA, ABS, PE, PC ...)

The whole process starts in our tool design department, where the idea of the appearance of the new product gets its first form. This is an extremely important phase in the construction of the product because it has the greatest influence on the later tool construction and spraying of the positions on the machines.

Then, in our toolkit, based on the design of the model, the tool is developed. Plastic injection molding tools are also the most complicated and complex tools, but the combination of years of experience and acquired knowledge and skills in machining have resulted in our ability to make very complex positions.

After the production of individual components and assembly of tools, testing and injection of test samples are performed, after which we start spraying our products.

Long-term exploitation of the tools with the production of large series of products sufficiently speaks about the quality of production.

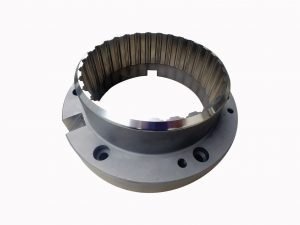

Apart from the production of tools, we also perform machining, milling, grinding, drilling, grinding, erosion of different types of steel, plastic and assembling of assemblies. Through the system from drawing to finished components, using modern processing methods, we are able to make the most varied and complicated machine positions. Our production capacities are focused on both individual and small-scale production.

With great experience, precision and committed work in the production of automation and robotization positions in the automotive and aviation industry, for customers across Europe, we are a reliable partner that will meet all the requirements regarding quality and delivery deadlines.

Our department for making tools consists of:

- CNC machining center

- more CNC milling machines,

- CNC lathe,

- several classic lathes,

- machine for flat, circular and coordinate grinding,

- electro-erosion machines,

- erosite with wire,

- eccentric press,

- machine for making gears,

- 3D measuring machines,

- engraving position laser,

- furnaces for thermal processing of materials.‚